Quality, Cost, Delivery. The mantra for any purchasing professional. Increasingly it appears that cost is becoming the key driving force in the purchasing decision.

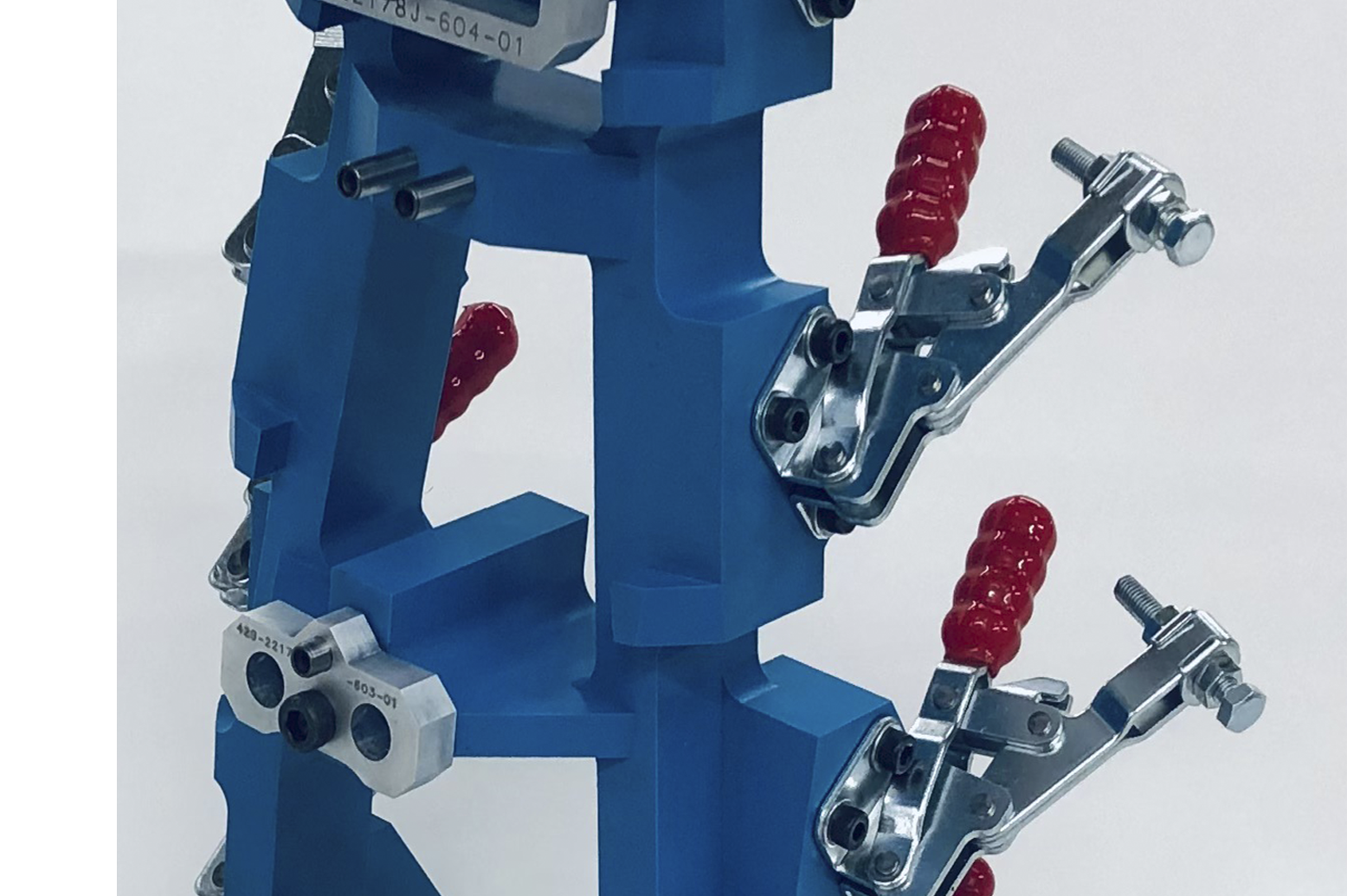

It's a difficult dilemma for a buyer. The checking fixture is a necessity - needed to assure product quality, and contribute towards profitability by reducing scrap. But it comes at a cost.

Going for the cheapest option available will minimise your initial outlay but may mean you are compromising on functionality and tool life. Inevitably, a fixture is going to be ‘cheap’ for a reason, and you should probably consider the following before you go down the lowest cost route.

Specification

One of the easiest ways for your cheapest supplier to take cost out of a fixture is to skimp on the specification. This could mean not including steel contact points in a tooling board body, or including smaller (and fewer clamps) than are needed to properly secure a part, or going for 10mm thick aluminium baseplate when it’s obvious that 20mm is the right choice. Once you’ve made your purchasing decision, you don’t want the CAD review stage to be the first time that you find out about the 'lite' solution your supplier is proposing.

Make sure the specification you issue with your RFQ is sufficiently comprehensive that your cheapest supplier is not afforded licence to skimp. And then make sure that their quotation actually meets the specification. That way, you’re more likely to get the fixture that you thought were buying.

Cutting corners

Your cheapest supplier has been awarded your business, and he’s underway with manufacturing your fixture. But he’s cheap, which could mean that the quality of your fixture is not what it could be.

By cutting corners your supplier will be able to preserve his bottom line. This could include:

- Further skimping on specification e.g. going for a lower grade, less robust tooling board for the fixture body.

- Not reviewing the CAD design thoroughly and hoping that any issues that could have been identified at this stage don’t crop up.

- Rushing through the manufacture of the fixture. Don’t be surprised when sight lines are missing, or support pillars come loose.

- Limiting quality assurance processes, e.g. giving your fixture a brief once-over with the CMM just to generate a report rather than undertaking a robust, extensive verification.

Cheap and cheerful has its place, but not in fixture manufacturing. By better balancing cost vs benefit you’ll improve your chances of buying a fixture that is actually fit for purpose for the entirety of its intended life.

Long lead times

If you’re on a compressed time scale, and on time delivery is critical, then going for the cheapest option may not be the right choice for you.

Short lead times can be costly for a supplier. Overtime is expensive, and your cheapest supplier will want to avoid out of hours working.

That four-week lead time you needed may become five or six. Yes, you’ve saved money buying your fixture but the delays to your programme caused by your fixture not arriving when promised could ultimately end up costing you more.

Aftersales support

How confident are you that, once the fixture has been delivered, your supplier is willing & able to support you in ironing out any issues that may only become evident once it been put in to use?

A cheap supplier will be more resistant to providing further after sales support. He has costs to control and won’t want to provide any further service free of charge. Don’t be surprised if that light weighting or clearance adjustment comes with an extra bill. Your cheap fixture just cost you that little bit more than you thought.

In Summary

As with most things in life, you do tend to get what you pay for.

Rather than choosing the cheapest option you can find, consider value for money as the better solution – balancing benefit versus cost. It may cost you more at the start, but you can be confident that, in the long term, you’ve made the right choice.

If you'd like to discuss the value for money approach that we offer then we'd love to hear from you. Let us know you'd like to talk by requesting a call back.

Learn more about how you can save both time and money procuring your next checking fixture with our free guide Buying Checking Fixtures Better.

For more content like this, follow us on LinkedIn by clicking the button below.