Providing your checking fixture supplier with the best possible RFQ is always a good idea – you’ll get back a proposal that is tailored to your unique requirements, and you’ll save yourself time and money too.

We’re often asked how much a checking fixture will cost. This will vary for each project, so obtaining a precise quotation is extremely important. A detailed RFQ minimises unexpected costs, reduces the risks of over or under specifying and makes it easier to compare quotes between different suppliers.

As a buyer, it can be frustrating to be supplied with a quote that perhaps isn’t quite as accurate and thorough as it should be, with implications on lead time and potential further cost. To ensure you receive the most accurate quotation possible from your supplier, it’s important to give them as much detailed information on your specification and project requirements right at the beginning.

Considerations to discuss with your supplier for a precise quotation

Below are some of the considerations and additional information we recommend discussing with your checking fixture supplier.

1. Do you have CAD data for your component?

The more information regarding your components geometry and dimensions the more accurate the quotation. Most suppliers will prefer CAD data to be available with the RFQ, as this enables them to view the full geometry of the part and establish dimensions for the fixture. If you have 2D drawings or a component sample, this will enable a quotation to be generated. However, this does come with a cost implication, as the supplier will need to construct a 3D component CAD model prior to manufacture.

2. What is the material specification for the fixture?

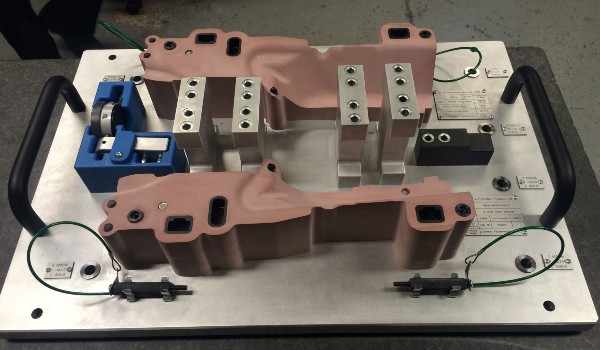

Depending on the application of the fixture, different materials can be used. Tooling board offers a cheaper alternative to aluminium but your product and / or production schedule may require the more robust option of aluminium or steel. If you are unsure, it is worth discussing with your supplier as, in some cases, it may be more cost effective if the fixture is manufactured from different materials (i.e. aluminium base plate, tooling board body with steel net pads).

3. How is the component to be held and positioned during inspection?

Indicating features of the component you require to be used as datum positions is critical, and must be included in your RFQ. They could be holes, slots or other features on the component, used to ensure that each individual part can positioned on the fixture with assured repeatability.

RPS points are used as a reference from design concept through to manufacture and inspection of completed components. These are identified and lock a part in six axes to create a perfectly controlled alignment.

Components can be requested to be inspected “In Car Line” which requires the part to be positioned in the same plane as it is situated in the vehicle. This may require towers to be included in the fixture design to hold the component in position, with additional cost implications.

4. What type and level of inspection is required?

There are a wide variety of inspection procedures that can be requested, and these will ultimately influence the cost of a checking fixture. Understanding the impact that these have on cost and lead time is vital for generating a clear RFQ.

- Simple fixtures may only require a sight line around the component. This can be achieved by engraving the outline profile of the component on to the fixture, which enables an operator to sight check the form. These lines may be colour coded and include dimension labelling.

- DTI’s (Dial Test Indicators) or force gauge points may be requested for areas to be inspected on single components or assemblies.

- Gap & Flush checks might also be needed. This means that the component form is replicated around the outside profile or surface, and an undercut is machined at a set distance below the form. A straight edge or step gauge can used to check that the component is flush with the profile and a plug gauge (wand) or taper gauge is used to check uniformity of the underside of the component. These tend to be used for the checking of parts during manufacture by the operator at machine-side.

- A CMM (Coordinate measuring machine) or scanning devices may be used for inspecting the finished products. The design of the fixture must allow for access of the probe or scanning device around the areas to be checked.

5. Include and check additional manufacturing considerations

It’s important that the sketches of the proposed design are available from the supplier to make comparing like-for-like quotes much simpler. These will give you a good indication of how your RFQ has been interpreted by your supplier, and allow you to view the quotation with more clarity.

6. What are the checking fixture finishes needed?

Specifying the finish needed, for example whether the fixtures require painting or anodising, is important to include at the RFQ stage. This will reduce the need for unexpected add-on costs.

Final thoughts

Many companies supply a detailed gauge specification with their RFQ listing all the points raised and more.

Standardising the information you send to your supplier, as well as taking the time to discuss the RFQ thoroughly, will help you obtain the most precise quotation possible. This will save you time and money, making it easier to compare like-for-like offers, as well as reducing the possibility of unexpected costs arising from inaccurate/ incomplete quotes.

If you'd like to discuss your RFQ or any part of your checking fixture project, then we’d love to hear from you. Let us know you'd like to talk by requesting a call back.

Want to learn more? Why not check out another one of our blogs? You might enjoy reading Are you making any of these checking fixture buying mistakes? or 10 Great Questions To Ask Your Potential Checking Fixture Supplier.

You can learn more about how you can save both time and money procuring your next checking fixture by reading our free guide Buying Checking Fixtures Better.

For more content like this, you can also follow us on LinkedIn by clicking the button below.