A couple of weeks ago, the team sat me down to ask questions we hear a lot from our fixture customers. The video is part of our buyer’s guide series, which aims to provide time-and-money-saving wisdom to those in the manufacturing industry.

In this clip, I’ll be talking all about:

-

What exactly influences the price of a checking fixture

-

If special options are available

-

When you might need more than one checking fixture

Watch the video or read the summary to learn more.

How much does a checking fixture cost?

Medium-sized fixtures for profile checks will be the cheapest, from around £2,000.

On average, a medium-sized checking fixture designed for dimensional checks is between £5,000 - £8,000.

For very large, complicated components held in car line, checking fixtures can range from £25,000 or even £50,000 depending on the complexity of components and assemblies.

You can find out more about how much a checking fixture costs by reading our blog.

What influences the price of a checking fixture?

In short, the price of a checking fixture is dependent on the complexity of component, how much detail must be checked, and the checking method.

For a simple form gauge, we’ll cut a CAD form to the existing form, and perform an outside profile and Gap check.

Checking fixtures become more expensive when dimensional checks are needed with complicated forms, as well as CMM checks.

A checking fixture’s size will influence the cost with materials and cutting time etc. But price is mainly dependant on the intricacy of the fixture’s design.

Are there special options?

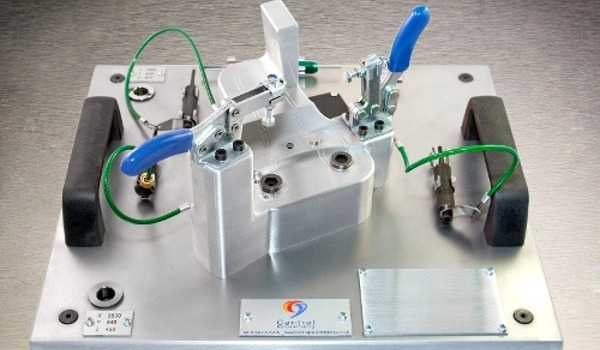

Yes. And it’s better to specify any special options, such as pneumatic clamping, right at the beginning of the buying process.

Whether or not pneumatic clamping will add on much in terms of price, again, all comes down to dimensional complexity, and what & how you’re inspecting.

In the automotive sector, the majority of components are held in car line. That means they’re actually held on the fixture in the same way they would be assembled in the vehicle. This helps build a picture on inspection of how the component will fit into the vehicle.

This process can take a small fixture – 300mm or 400mm, for example – to a meter high, because it’s held in that plane.

If you’re looking to inspect on a CMM, the probe has to access underneath the component. Sometimes, this means it could be raised a further 200mm from the base as well.

So, for example, you can have quite a big component laid flat on the floor, then raised 200mm, and then an extra 300mm, 400mm in the air. You’ll then need to build posts up to that height to support the component.

When do you need more than one checking fixture?

There are some cases where more than one checking fixture will be necessary. For example, in a large company with 30 or 40 machines running on one CMM, multiple fixtures will reduce backlogs.

If you’d like to discuss a project with us, we’d love to hear from you. Let us know you'd like to talk by requesting a call back.

If you found this content useful, why not read our checking fixtures buyer’s guide? It contains practical advice for getting the best value out of your checking fixture.

For more content like this, follow us on LinkedIn by clicking the button below.