Here at Central Patternmaking, we design and manufacture PU foam tools, RIM tools, RTM tools, and vacuum forming tools.

And one of the questions we’re asked most often, often before even receiving an RFQ, is “how much will it cost?”

But, as with any bespoke product, there are so many variables that providing an exact cost calculator would be impossible without a full specification.

So while I can’t say “your mould tool will cost X amount” with any certainty without full specification, there are plenty of cost-related factors that you should be aware of. These include:

- Application

- Number of Impressions (Cavities)

- Material

- Geometry

If you want to understand how each of these factors influence the cost of mould tooling, you’re in the right place.

Read more:

Why Having Multiple Suppliers is a Great Idea

The Secrets to Successful Lights-Out Machining

Tooling Boards: Which One is Best for your Project?

Application

Based on your intended process, you’ll probably already know what type of tooling you need. Each type of tooling has its own price range and variables that can increase or decrease tool cost:

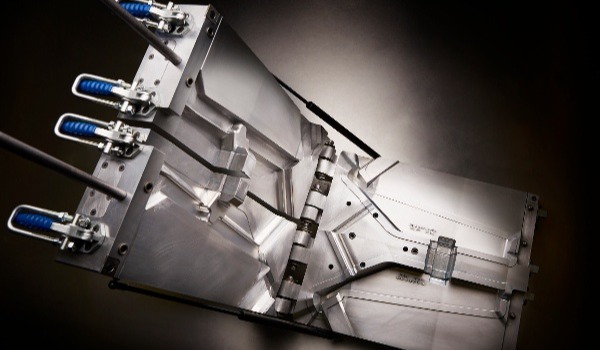

- For reaction injection moulding, tooling can vary greatly in size, geometry and grades of materials processed. Prototype tooling, or tooling for low-volume projects, can be manufactured from cheaper materials such as tooling board or resin. For more complex parts, or high-volume production, aluminium tends to be used, slightly increasing the cost. RIM tooling can cost anywhere from £1K to £50K+.

- We manufacture tooling for compression moulding manufactured from aluminium or steel. Component dimensions, complexity and the number of impressions will have the biggest impact on tool cost. Compression mould tooling can cost anywhere from £2K to £50K+.

- Rotational mould tooling, as with compression mould tooling, is generally manufactured from steel or aluminium, due to the process. Again, as with compression tooling, component dimensions, complexity and the number of impressions (Gemini moulds) will have the biggest impact on tool cost. Rotational mould tooling can cost anywhere from £2k to £50K+.

The application of the tooling will also dictate what add-on features are required. For example, for PU and RIM tooling, does the tool need to be mounted separately on a mobile stand? Is a hinged opening mechanism with clamps required? Are waterways needed? What about inserts? For rotational moulds, what framework is required to encase tooling? How many sections of tooling are required?

The more separate aspects there are to a mould tool, whether that be a waterway system or a ventilation system, the longer it will take to produce and assemble, and so the more it will cost.

Impressions

More impressions means that a single tool can produce more parts, but more impressions also means more expensive mould tooling.

The key here is finding the cut-off point where a multi-impression tool becomes the cheaper option. This will be down to the production volume.

If the cycle time exceeds the takt time, a multi-impression tool will reduce the cycle time per part.

Material

The right choice of material will be largely based on the volume of parts required, timescale, and budget.

Let’s take resin or tooling board for example: ideal for small lifespan production or prototype PU mould tooling, they have the benefit of reducing cost and lead time.

On the other hand, aluminium billets or cast aluminium are typically used for larger production requirements and/or longer lifespan projects.

Your component might also require a specific surface finish which needs to be applied to the mould, and/or heat/cooling transfer, which can narrow down your choice of materials.

Aluminium & steel offer the advantage of good thermal transfer used in cooling or heating the mould, whilst also offering the option for spark eroded, etched or polished surface finish.

Resin and tooling board are more limited in the surface finishes they can offer you, and have very little thermal transfer.

Read more:

5 Axis vs. 3 Axis CNC Machining: which is best for my tooling?

How can you reduce the cost of your next mould tooling project?

PU and RIM Mould Manufacture: How does design affect cost & performance?

Geometry

Dimensions have a major influence on cost. The larger the size, the more materials required and the longer the machining time.

And it’s not just size – mould tools without internal geometry will typically only require a simple design. However, a more complex part will need a more intricate mould tool design – the cost of which will be greater.

Think of it this way: machining a 1m x 1m flat table is going to be much quicker and simpler than machining a 1m x 1m replica of the Shropshire hills. The complex shape of the second example means that the tool path would be much longer, with multiple passes required, increasing machining time. It’s the same concept with mould tooling – and more machining time means a higher price. Therefore, a mould tool design incorporating individual inserts, cores or over moulded parts will be more expensive.

So, there you have it, our guide to mould tool pricing.

To find out exactly how much your mould tooling is going to cost, you will need to get a quote.

For more content like this, follow us on LinkedIn by clicking the button below.