-

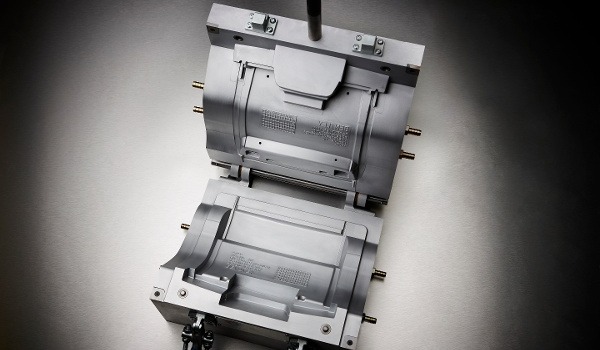

How can you reduce the cost of your next mould tooling project?

When buying a mould tool, we understand that cost will likely be one of the most important factors when choosing which supplier to buy from. If approached correctly, there are several ways to reduce the cost of mould tooling. learn more...

When buying a mould tool, we understand that cost will likely be one of the most important factors when choosing which supplier to buy from. If approached correctly, there are several ways to reduce the cost of mould tooling. learn more... -

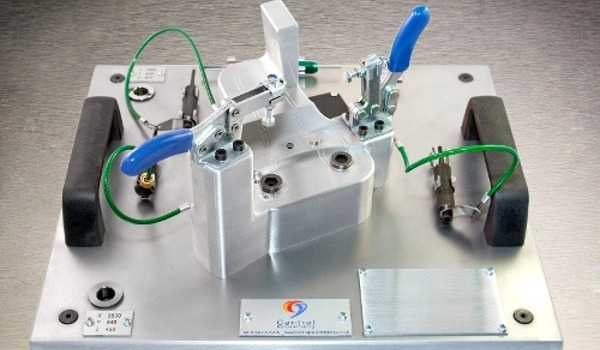

What influences the price of a checking fixture?

A couple of weeks ago, the team sat me down to ask questions we hear a lot from our fixture customers. The video is part of our buyer’s guide series, which aims to provide time-and-money-saving wisdom to those in the manufacturing industry. learn more...

A couple of weeks ago, the team sat me down to ask questions we hear a lot from our fixture customers. The video is part of our buyer’s guide series, which aims to provide time-and-money-saving wisdom to those in the manufacturing industry. learn more... -

Buy Better Foundry Patterns by Asking These Questions

/tooling-being-machined-1.jpeg) Ever wondered how you can get better-value tooling? Or how to ensure your tooling will be to the right standard? Or how to safeguard yourself against delivery delays? learn more...

Ever wondered how you can get better-value tooling? Or how to ensure your tooling will be to the right standard? Or how to safeguard yourself against delivery delays? learn more... -

How to Reduce the Cost of your Foundry Tooling

/Tooling-board-horizontal-Disamatic-pattern-1.jpeg) Cost. It’s one of the most important considerations when sourcing foundry tooling. learn more...

Cost. It’s one of the most important considerations when sourcing foundry tooling. learn more... -

Getting The Best Quote From Your Foundry Tooling Supplier

/Airset-pattern-produced-from-tooling-board-2.jpg) For most customers, when it comes to buying foundry tooling, there is one over-riding consideration: cost. And whilst the cost of foundry tooling is primarily dependent upon factors such as its size, material, and cavity geometry & complexity,... learn more...

For most customers, when it comes to buying foundry tooling, there is one over-riding consideration: cost. And whilst the cost of foundry tooling is primarily dependent upon factors such as its size, material, and cavity geometry & complexity,... learn more... -

How Much Does Pattern Equipment Cost?: Hidden Costs

/CENTRALPMJUNE2015425241-1.jpeg) You’ve just ordered your pattern equipment, and you think you know how much it’s going to cost. But the cost of your pattern equipment isn’t just the amount you’ll pay your patternmaker. learn more...

You’ve just ordered your pattern equipment, and you think you know how much it’s going to cost. But the cost of your pattern equipment isn’t just the amount you’ll pay your patternmaker. learn more... -

How Much does a Foundry Pattern Cost?

/Aluminium-horizontal-Disamatic-pattern-1.jpeg) A foundry pattern is a tool used to produce the sand moulds from which castings are made (from molten metal). The pattern impression is essentially a replica of the casting. learn more...

A foundry pattern is a tool used to produce the sand moulds from which castings are made (from molten metal). The pattern impression is essentially a replica of the casting. learn more... -

5 Axis vs. 3 Axis CNC Machining: which is best for my tooling?

You've probably heard about 3 and 5-axis machining. You might already know the basics: learn more...

You've probably heard about 3 and 5-axis machining. You might already know the basics: learn more... -

The Secrets to Successful Lights-Out Machining

Lights-out machining - it’s how we compress the lead times of our tooling supply. With one-off, bespoke and (often) high-value tooling to be machined, there’s no opportunity for proving out the intended machining process, and the stakes are high. learn more...

Lights-out machining - it’s how we compress the lead times of our tooling supply. With one-off, bespoke and (often) high-value tooling to be machined, there’s no opportunity for proving out the intended machining process, and the stakes are high. learn more... -

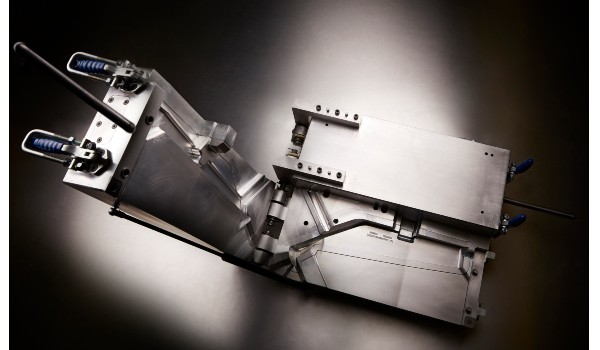

PU & RIM Mould Manufacture: How does design affect cost & performance?

At Central Patternmaking we work closely with a number of UK Polyurethane processors, producing tooling for a wide spectrum of components including automotive, aerospace, electronics, defence, point of sale and many more. learn more...

At Central Patternmaking we work closely with a number of UK Polyurethane processors, producing tooling for a wide spectrum of components including automotive, aerospace, electronics, defence, point of sale and many more. learn more...

Home » Blog